Leading the field in technology with less energy and fewer emissions

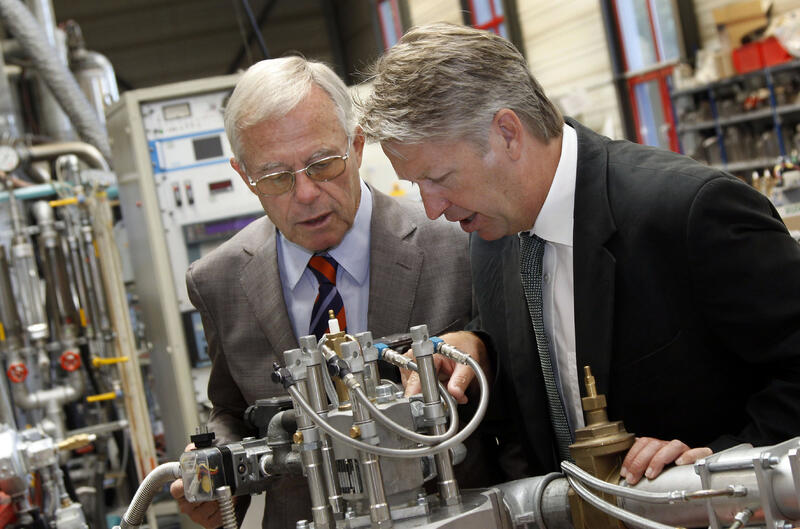

Renningen. “The Wünning father-and-son team stands for the harmonious combination of economy and ecology. Their successful business activities, together with their world-class technological and scientific achievements, have been an important factor in bringing about a more efficient use of energy and a considerable reduction in emissions during high-temperature processes, such as in the production or steel and glass and in the chemical industry – and in making Germany a global market leader in this sector.” – This is how Dr Fritz Brickwedde, the secretary general of the Deutsche Bundesstiftung Umwelt (DBU), today announced the presentation of the 2011 German Environmental Award of the DBU to the managing directors of the company WS Wärmeprozesstechnik (Renningen), Dr Joachim Alfred Wünning (81) and Dr Joachim Georg Wünning (48). German President Christian Wulff will present them with the award – the most lucrative environmental prize in Europe – in Stuttgart on 30 October. The prize money totals 250,000 euros.

© DBU/Karin Rebstock

FLOX makes "a considerable contribution to saving energy and avoiding air pollution"

The rapid global increase in energy consumption, along with a rise in emissions of carbon dioxide, nitrogen oxide and particles, have made saving energy and emissions reduction the “No. 1 topic” worldwide, Brickwedde said. He said that a large part of energy consumption was due to the steel, glass and chemical industry, whose high-temperature processes were particularly energy-intensive. “The combustion technology of flameless oxidation – also called FLOX – that has been developed by today’s prize-winners can make a considerable contribution to saving energy and avoiding air pollution,” Brickwedde said.

Nitrogen oxides that can irritate and damage lungs are avoided

The principle of “fire without a flame” in the FLOX burners is based on a sophisticated mixture of combustion air and gas, along with flue gases that constantly circulate and are fed back into the cycle. During this process, no flame in the usual sense is created – though in fact, it is just no longer visible with the naked eye. Instead, the fuel burns “invisibly” and evenly throughout the entire combustion chamber and not only where the flame is, as with conventional procedures. This evenness of combustion avoids peak temperatures, which otherwise lead to the formation of large amounts of nitrogen oxides during the combustion process. Nitrogen oxides can irritate and damage lungs, and are also a factor in acid rain, smog and ozone creation. “In this way, the FLOX process makes temperature, combustion and emissions very easy to manage,” Brickwedde said.

Pioneering example of the compatibility of economy and ecology

Brickwedde went on to say that improving energy use in energy-intensive branches of in-dustry while guaranteeing that the product quality remained the same or improved was a challenge for the future. “The Wünnings recognised immediately that FLOX combustion has great advantages in this regard. This controlled and even process combined with the use of waste heat enables fuels to be used more efficiently,” he said. The procedure also met the high technological and scientific demands of practical use, he added, saying it was a technological example that showed how ecology and economy were compatible with one another. Summarising the DBU’s decision to award the prize to the Wünnings, Brickwedde said, “In short, these are ‘seven-league boots’ for environmental and climate protection.”

© DBU/Karin Rebstock

FLOX technology – convincing solution

Brickwedde stated that in an economic sense as well, FLOX technology was greatly su-perior to previously established end-of-pipe waste gas cleaning processes. He said the fact that it had been so quickly developed and successfully put on the market underlined the practical relevance of the procedure. Brickwedde stressed the significance of the technology: “Other manufacturers have also developed their own burners on the Wünning principle. This imitation shows how convincing this solution is. It not only greatly eases the burden on the environment, but has set new standards worldwide.”

Interdisciplinary cooperation makes FLOX procedure useable in other fields

The comparatively open sharing of research results and the intensive cooperation of the company WS Wärmeprozesstechnik with many prestigious international institutions had been of great importance in this regard, Brickwedde said: “The FLOX procedure could only be adapted for other fields of application owing to interdisciplinary cooperation.” In closing, Brickwedde urged the prize-winners, “Surprise us again soon with more out-standing solutions like these in the field of environmental technology!”

A note on FLOX technology

“FLOX” is an abbreviation for “flameless oxidation”, i.e. combustion without a flame. This phenomenon was first observed in 1989 by Joachim Alfred Wünning in a combustion chamber at his company WS Wärmeprozesstechnik. The process was then developed further under the supervision of his son Joachim Georg Wünning in years of complex research. With traditional flame-based combustion in the high-temperature area – above all, the burning of fossil fuels and waste – large quantities of nitrogen oxides (NOx) are frequently produced. These are precursors for the formation of acid rain and ozone, and are damaging to health and the environment. FLOX technol-ogy makes it possible to have high-temperature processes during which the proportion of NOx in the flue gas is more than ten times lower than with traditional flame-based combustion, despite high preheating of the air to over 700 degrees. In the FLOX procedure, the combustion air necessary for the reaction flows into the combustion chamber at high speed through special nozzles, where it first draws in several times as much flue gas before mixing with the fuel. If the nozzles are arranged properly, the fuel oxidises very evenly without any flame at temperatures of over 850 degrees.

© DBU/Karin Rebstock